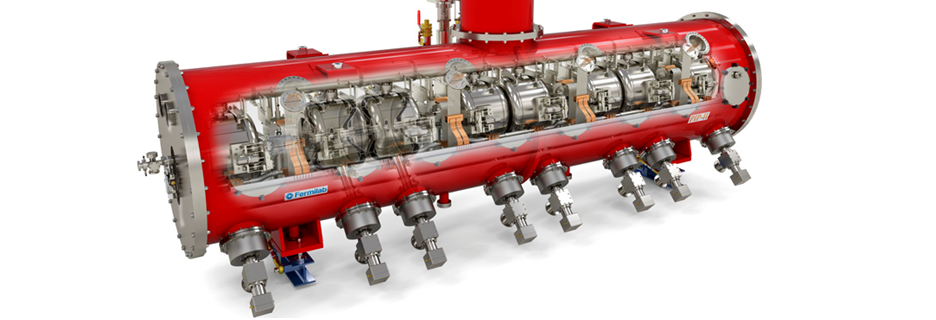

SRF Program maintains a diverse portfolio of research directions in SRF aligned with the needs of the DOE HEP, Office of Science, and the world-wide accelerator community.

The key focus of the research is on ways of dramatic improvement of the cavity performance (quality factor and achievable accelerating gradient), cutting costs, as well as full understanding of the underlying physics and materials science.

The individual research areas are led by an expert staff recognized by multiple awards including three DOE Early Career awards, Hogil Kim prize, PAST awards, as well as various conference poster and presentation prizes.

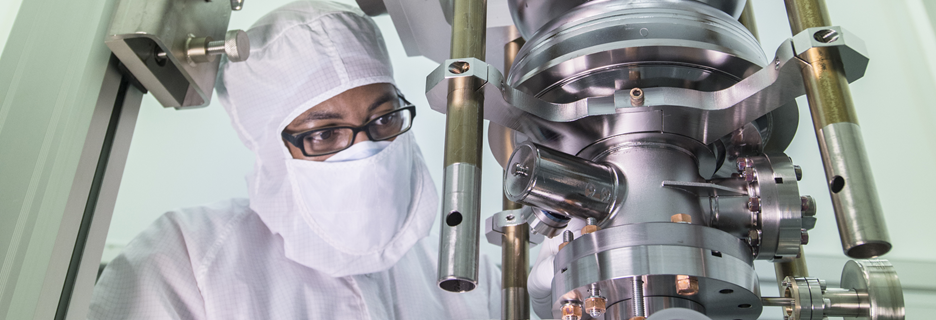

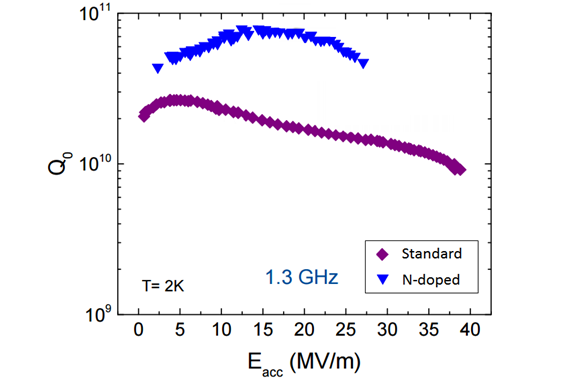

Nitrogen Doping

High quality factors (Q) are extremely important to accelerators with high duty factor, due to the infrastructure and operating costs of the cryogenic plant. In 2012, a process was discovered at FNAL to achieve unprecedented Q values by treating them in a high temperature furnace with a low pressure nitrogen environment. Large progress has occurred in the past two years on nitrogen doping processing development and in the understanding of the root of the improved performance thanks to samples surface studies. Following rapid development, the technology is now ready for being used in the LCLS-II accelerator with the potential to cut the cryogenic losses of this machine by a factor of two. The understanding of the underlying phenomena leading to the higher quality factors is being pursued theoretically and experimentally, and research towards an optimal doping treatment – which would give high Q at even higher fields (>25 MV/m) is ongoing.

A substantial improvement in quality factor is observed after nitrogen-doping.

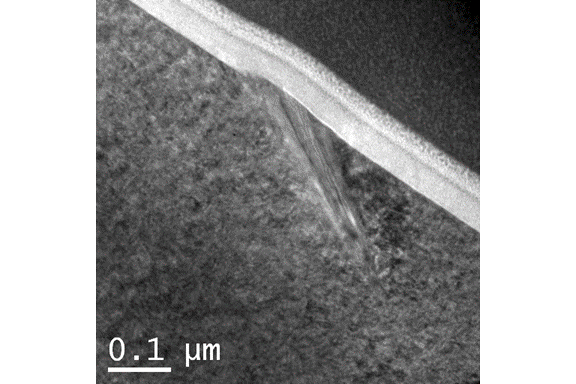

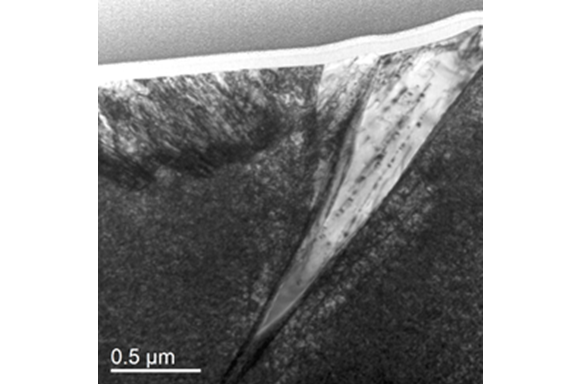

TEM cross sectional image of a nitrogen-treated layer prior to electropolishing to remove nitrides.

Efficient Meissner Expulsion

Ambient magnetic field present during the cooling of the cavities through superconducting transition temperature of niobium (9.25K) can be trapped and cause additional dissipation lowering the quality factor. It was discovered at Fermilab that the efficiency of the Meissner effect is dictated by the thermal gradient present at the superconducting-normal front during transition. New cooling schemes and procedures have been developed to maximize the expulsion of the magnetic flux to maintain the ultra-high Q factors all the way through from vertical tests to cryomodule environment.

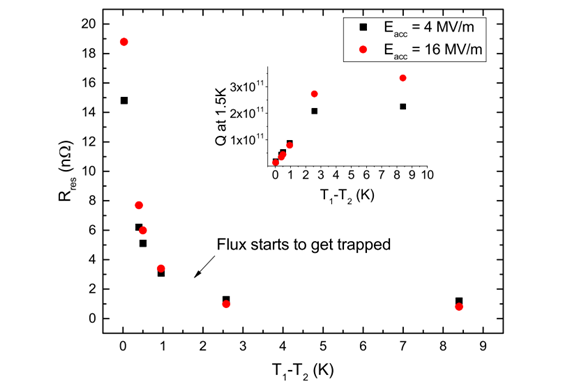

Residual resistance at 1.5 K as a function of the temperature gradient present at the normal/superconducting front as measured when equator reaches Tc. Inset shows the corresponding Q values.

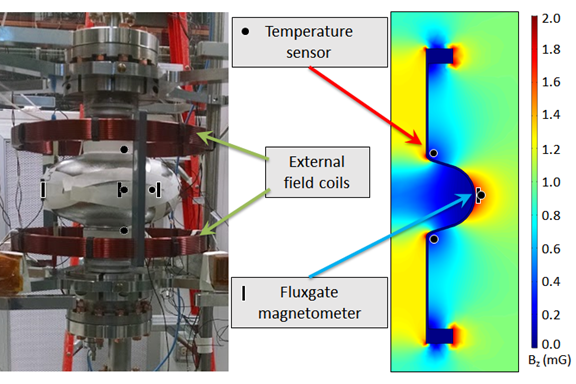

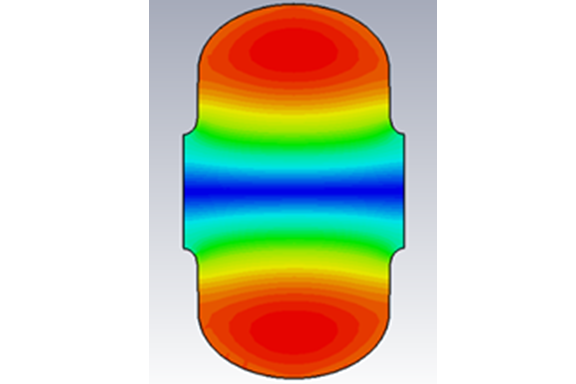

Apparatus for measuring magnetic flux expulsion in a 1.3 GHz single cell SRF cavity (left), and simulation of complete expulsion of a parallel field (right).

Nb3Sn-Coated Cavities

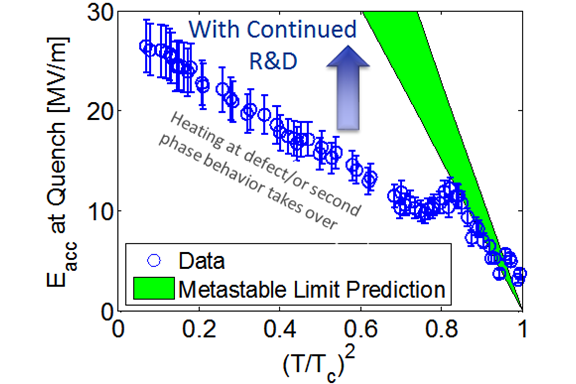

Traditional SRF cavities are made of niobium, and after many years of development, researchers have found preparation techniques that generate performances close to the fundamental limits of this superconductor. However, proposed next-generation particle accelerator applications are extremely demanding: using current technology, very large cryogenic plants would be required, and very long accelerator strings. The alternative superconductor Nb3Sn offers improved cryogenic efficiency (proven) and increased accelerating gradients (predicted). Researchers at Fermilab are developing an apparatus to coat niobium cavities with this exciting alternative material. The coating chamber will be large enough to accommodate even production-style cavities. This technology has the potential to offer dramatic improvements for large-scale applications in high energy physics, nuclear physics, and basic energy sciences. Because of their ability to operate at relatively high temperatures using a cryocooler instead of a cryogenic plant, Nb3Sn cavities can also have a transformational impact on small-scale applications in hospital treatments, university research, border security, and treatment of wastewater and flue gas.

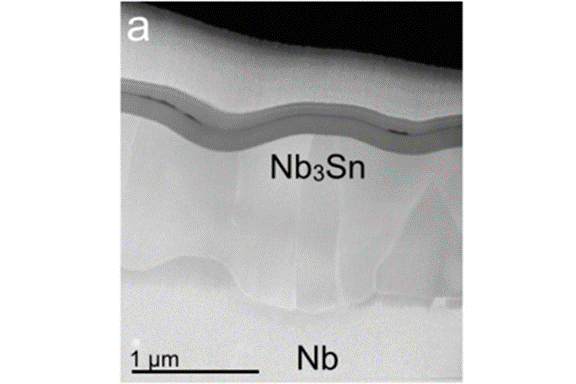

TEM cross sectional image of a Nb3Sn layer on a niobium substrate.

Additional R&D to improve coating quality is directed at bringing low temperature accelerating gradient of Nb3Sn close to prediction.

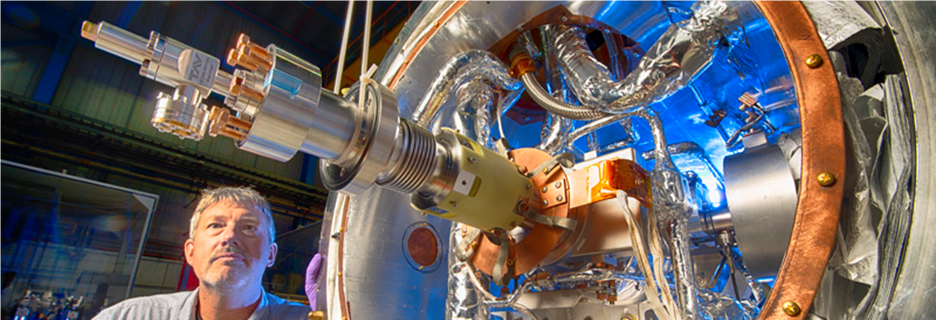

Material Cost Reduction

Superconducting thin film cavities have the potential to save tens of millions of dollars in materials costs for superconducting accelerators. Fermilab is developing innovative approaches to generate superconducting coatings on cheaper substrate such as copper cavities that will match or exceed performance of bulk niobium cavities. Two methods are being considered: ECR vacuum deposition and HiPIMS desposition. Both can generate highly ionized niobium atoms to deposit a coating in an energetic fashion. Innovative processing technology from solid niobium cavity development will also be incorporated in coated cavities.

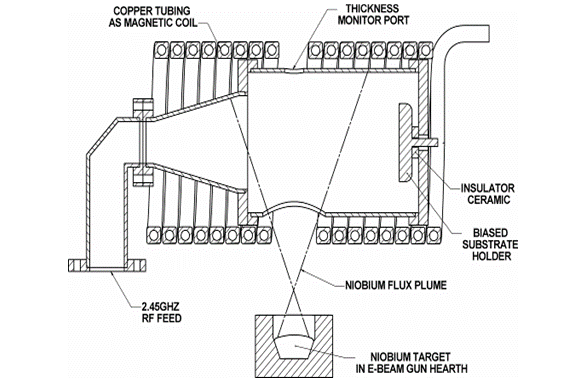

Illustration of deposition via ECR (Electron Cyclotron Resonance)

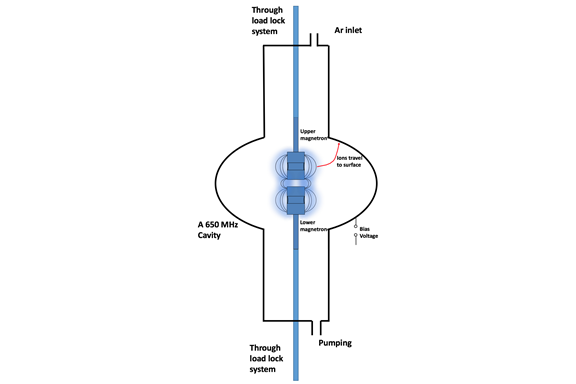

Illustration of deposition via HiPIMS (High Power Impulse Magnetron Sputtering)

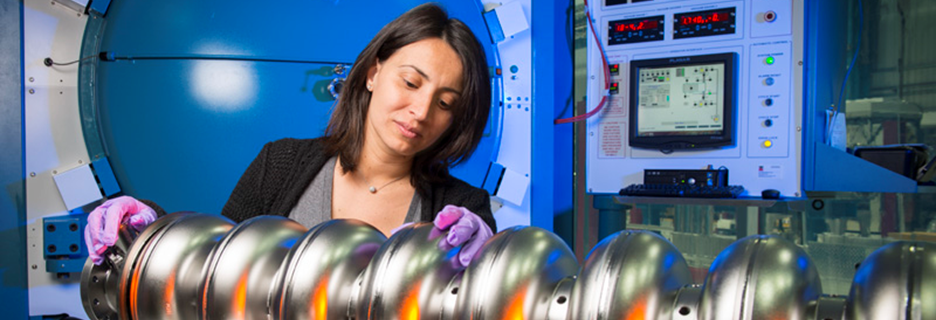

Fundamental Material Investigations

Increasing demand for state-of-the-art superconducting radio frequency cavities demands good understanding of the processes responsible for the cavities performance limitations. In the absence of the external degrading factors, SRF cavity performance is fully defined by the quality of the superconducting material which can be tailored by the temperature and chemical treatments. The region of interest for the superconductivity is localized in the near-surface layer of the cavity which is defined by magnetic field penetration depth. For instance, for traditional niobium, superconducting currents flow only within approximately the first 100 nm. Investigation of material structure and composition on nanoscale requires a set of advanced material characterization tools. On-site characterization techniques include SEM, EDS, EBSD, optical laser confocal microscopy with the cooling stage and sample polishing setups for the SEM sample preparation. Development of new SRF materials such as Nb3Sn, as well as cost reduction projects such as deposition of Nb on copper cavities, require extended material characterization as well as surface conditioning for traditional niobium. The combination of complimentary material characterization techniques, conducted either on-site or in other academic user facilities, provides insight into SRF performance-defining processes.

Niobium near-surface after the first step of N-doping (prior to material removal).

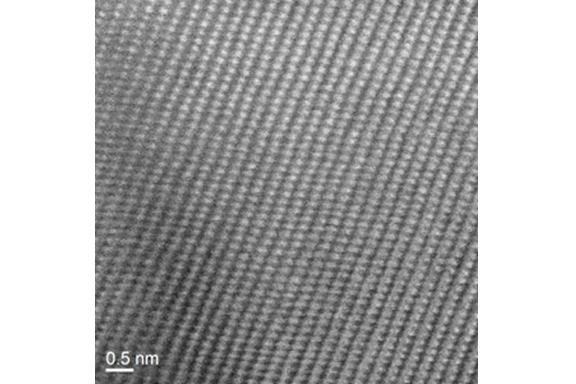

Aberration-corrected STEM image of the near-surface of Nb cavity

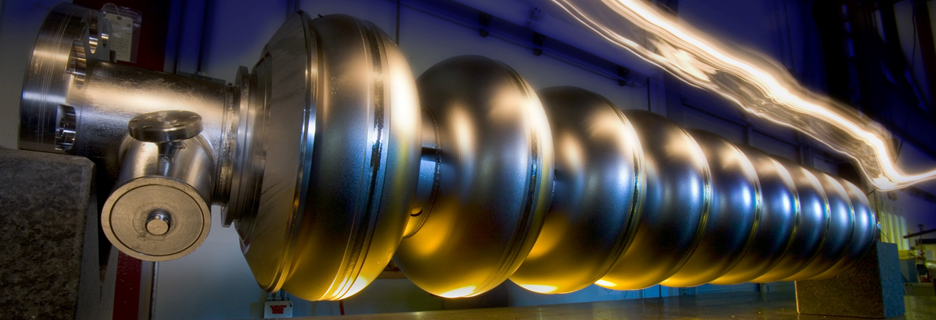

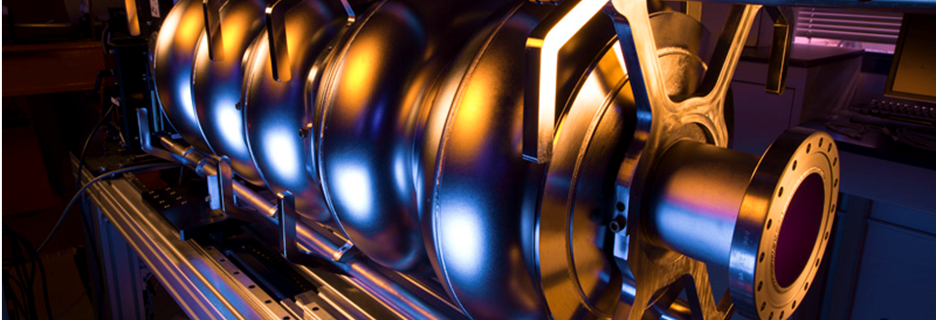

High Gradient Nb Cavities

A high energy linear collider accelerates charged particles up to energies of hundreds of giga-electric-volts to tera-electric-volts. Superconducting RF cavities provide the best beam quality in a cost effective way that saves tremendous electric power consumption. Increasing the acclerating gradient in a SRF cavity to its maximum is highly beneficial to reduce the accelerator length and reduce the construction cost. Fermilab is collaborating with the world leading SRF laboratories to advance niobium cavity technology to much higher usable gradient for future high energy accelerators. The development combines alternative cavity shapes and state of the art high quality factor processing technology.

Low loss shaped 2.6 GHz 1-cell cavity

Ichiro shaped 9-cell cavity in the cleanroom (courtesy Interactions.org)

Collaborators: