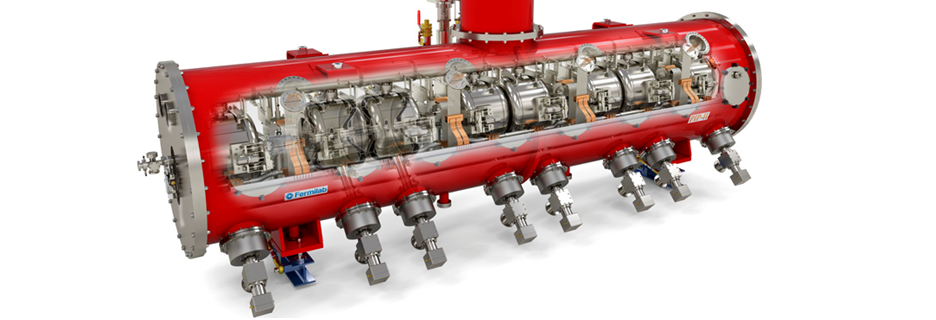

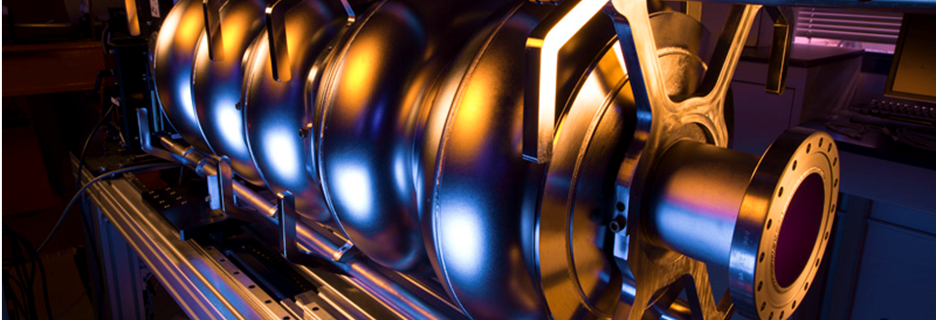

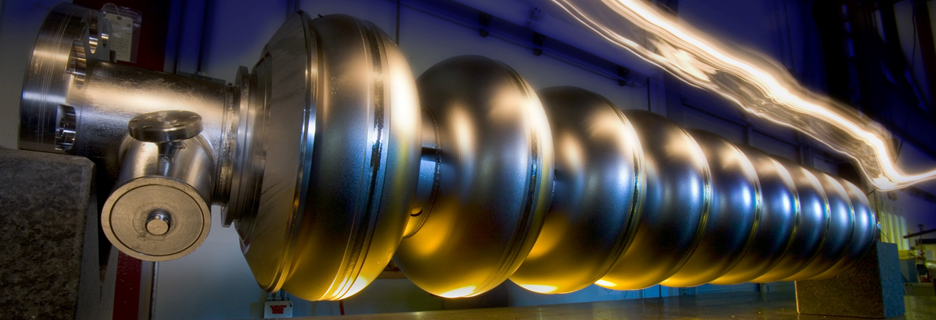

LCLS-II “High Energy” (LCLS-II-HE) is a planned upgrade project to the LCLS-II. Twenty-three 1.3 GHz cryomodules will be built by Fermilab and Jefferson Lab, each containing eight 1.3 GHz 9-cell superconducting radiofrequency (SRF) cavities. The cryomodule design remains nearly unchanged relative to the original LCLS-II superconducting linac. However, there is a significant change in cavity performance specifications. Motivated by limitations in available tunnel length, the average accelerating gradient is increased from 16 MV/m in LCLS-II to 20.8 MV/m in LCLS-II-HE, corresponding to a total module voltage of 173 MV. Like the original LCLS-II cryomodules, the LCLS-II-HE cryomodules will operate in continuous wave (CW) mode, meaning that achievement of high Q0 in the cavities is crucial to keep the cryogenic heat load manageable.

Fermilab’s scope of work for LCLS-II-HE includes:

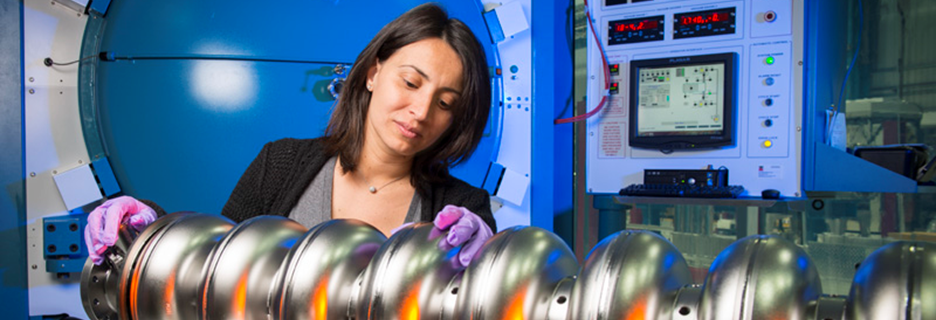

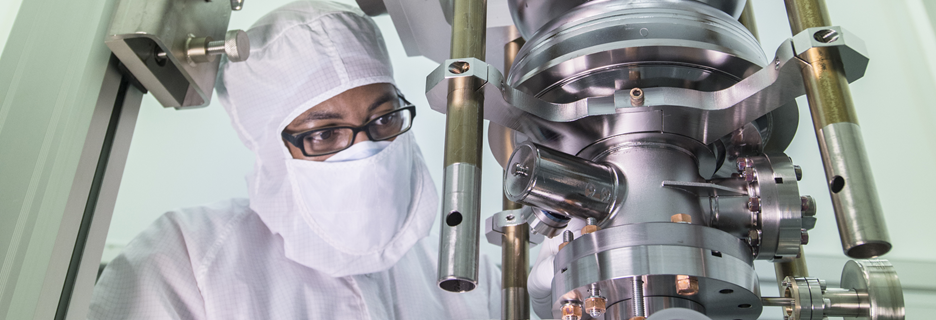

- High Gradient – High Q0 R&D program: LCLS-II uses the breakthrough nitrogen-doping technology invented at Fermilab to improve the quality factor (Q0), lowering the both cost of the cryogenic plant infrastructure and the operating costs. With the contributions from Fermilab, Jefferson Lab and SLAC, for LCLS-II-HE, an R&D effort has been successfully completed to develop a new cavity processing protocol and transfer the technology to industry.

- Design, fabricate, test & delivery fourteen 1.3 GHz cryomodules

- Fermilab is responsible for the design

- Fermilab and JLab share procurement of 1.3 GHz cryomodules parts

- Fermilab is responsible for the 1.3 GHz Buncher Capture Cavity cryomodule mechanical-cryogenic design

- Assistance to SLAC with design & procurement of cryogenic distribution system

- Assistance to SLAC with the procurement of cryomodule interconnect components

- For above deliverables provide installation and commissioning support at SLAC

Fermilab has successfully completed LCLS-II scope and has delivered the last LCLS-II cryomodule (CM) to SLAC in March 2021. LCLS-II CM production at Fermilab has brought technical readiness and important lessons learned for LCLS-II-HE. We have developed a strong team. We have proven that our team of people worked well together internally and externally and produced excellent results. The Fermilab team has demonstrated the capability of producing world record performance cryomodules on schedule and on budget.

LCLS-II-HE CM production at Fermilab has started on strong foundation and continues to deliver excellent world class results. To date, Fermilab has delivered four CMs to SLAC. Series cryomodules production is progressing well. SRF Buncher Cavity Cryomodule (BCC) final design review is completed.

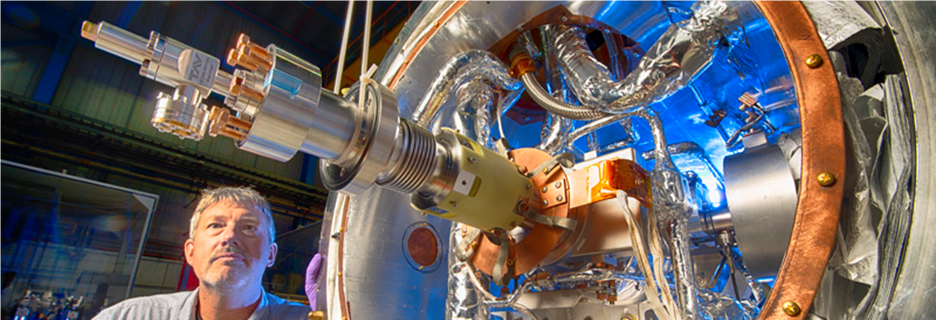

We have an amazing team of diverse, integrated technical personnel with extensive/proven SRF expertise/experience and support personnel with proven success to efficiently execute the project.

We continue to produce consistently excellent results and strive for continuous improvement. Our mission: Continue to produce world class cryomodules to support the LCLS-II-HE project Our motto: Let’s maintain focus! Safety and Quality are paramount to our success.

We are on schedule to deliver all the remaining Fermilab production CMs to SLAC before the linac installation work start for LCLS-II-HE.