To support its leading scientific research program on superconducting and conventional magnets, superconducting materials, magnetic measurements, Accelerator Support and state-of-the-art cryomodule production activities, the Applied Physics and Superconducting Technology Directorate maintains a long list of capabilities for conventional and superconducting magnets, from design through to test and quality performance check and mass production.

- Magnet Design

- Magnet Fabrication

- Magnet Testing

- Conventional Magnets

- Superconducting Strand and Cable R&D Lab

- Accelerator Support

Magnet Design

Within APS-TD we design magnets for future accelerators and experiments. From design to extended simulation, we use state-of-the-art tools, experience from years of practice and novel ideas to deliver the best magnets for the challenging requirements given to us. We also collaborate with other institutions, domestic and international, enriching the capabilities of and bringing advantages to both sides.

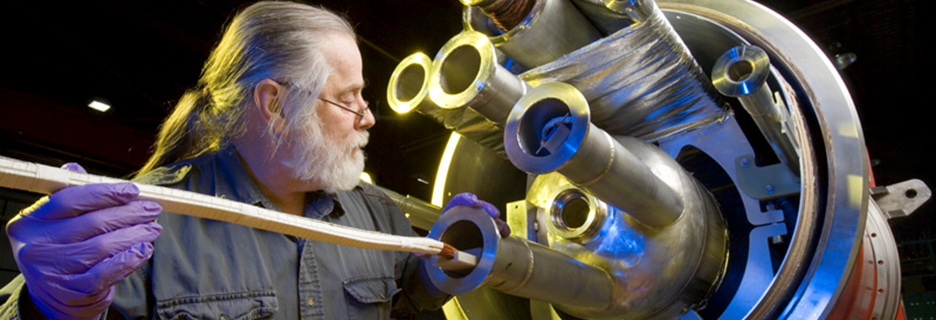

Magnet Fabrication

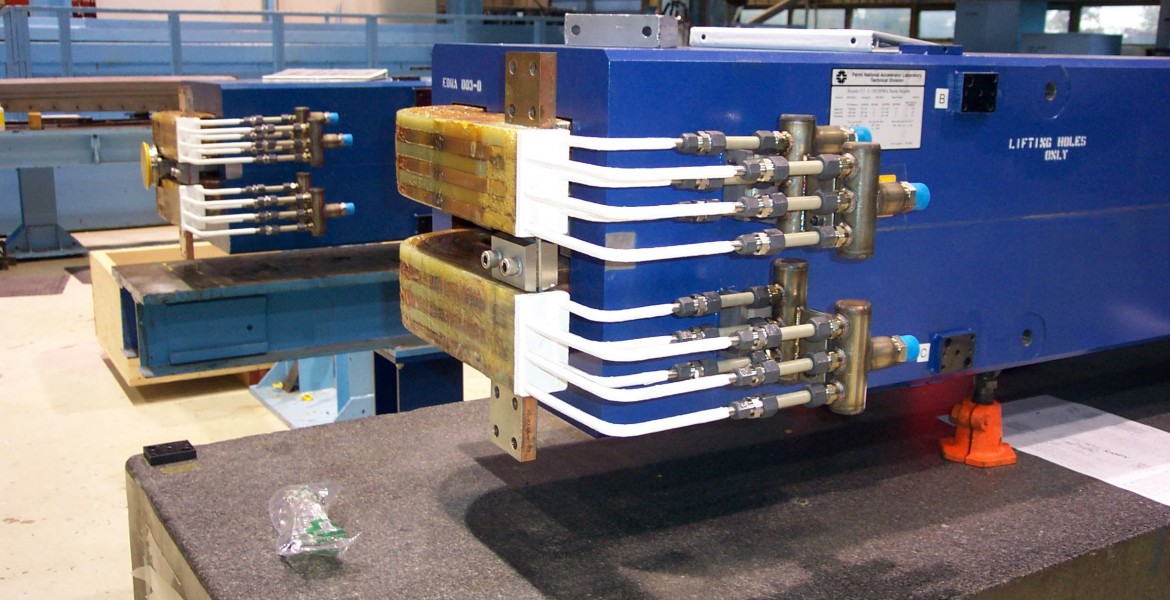

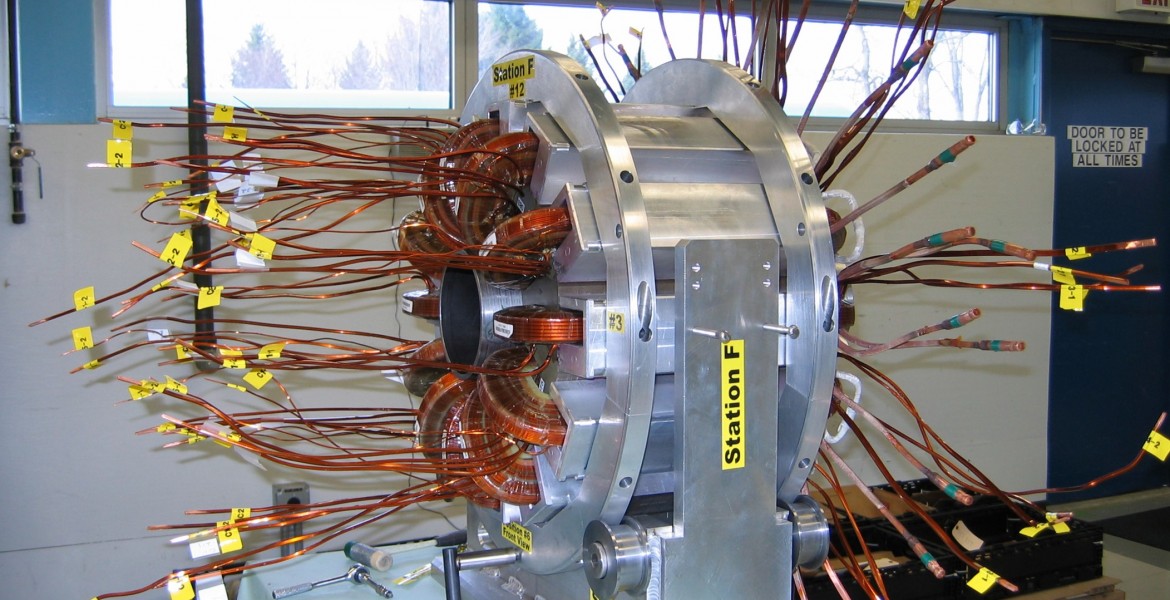

Fermilab has been at the forefront of superconducting magnet fabrication for particle accelerators since its inception, beginning with the Tevatron and continuing through the Superconducting Super Collider , the Large Hadron Collider, and many others. Capabilities include heat treatment and testing of conductors, as well as fabrication and testing of superconductor Rutherford-type cable and complete magnets, including their cryogenic housing modules.

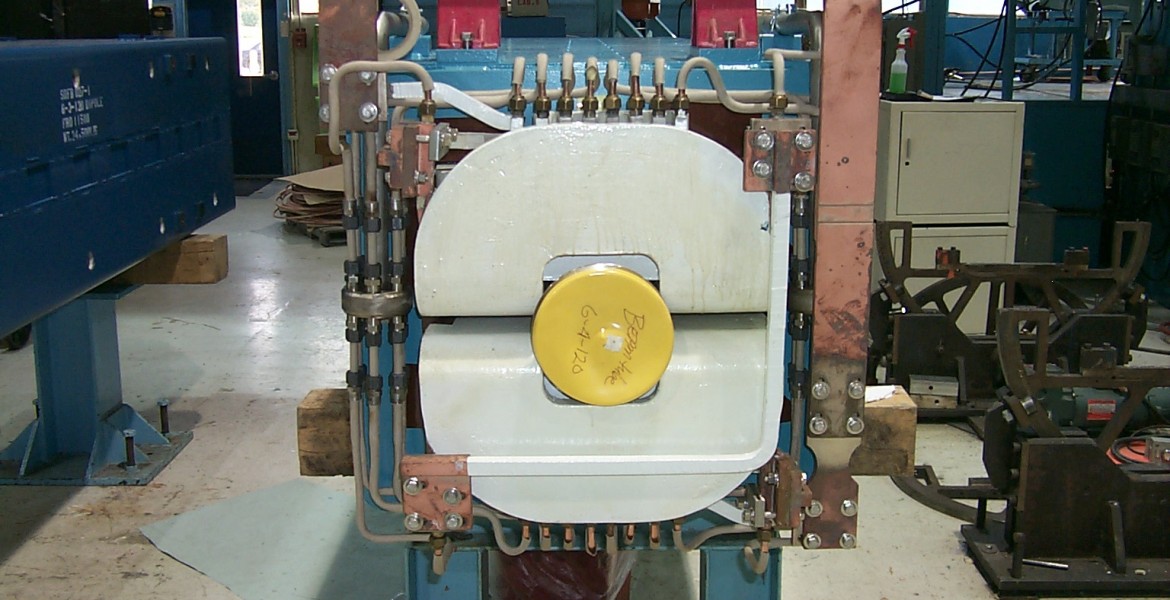

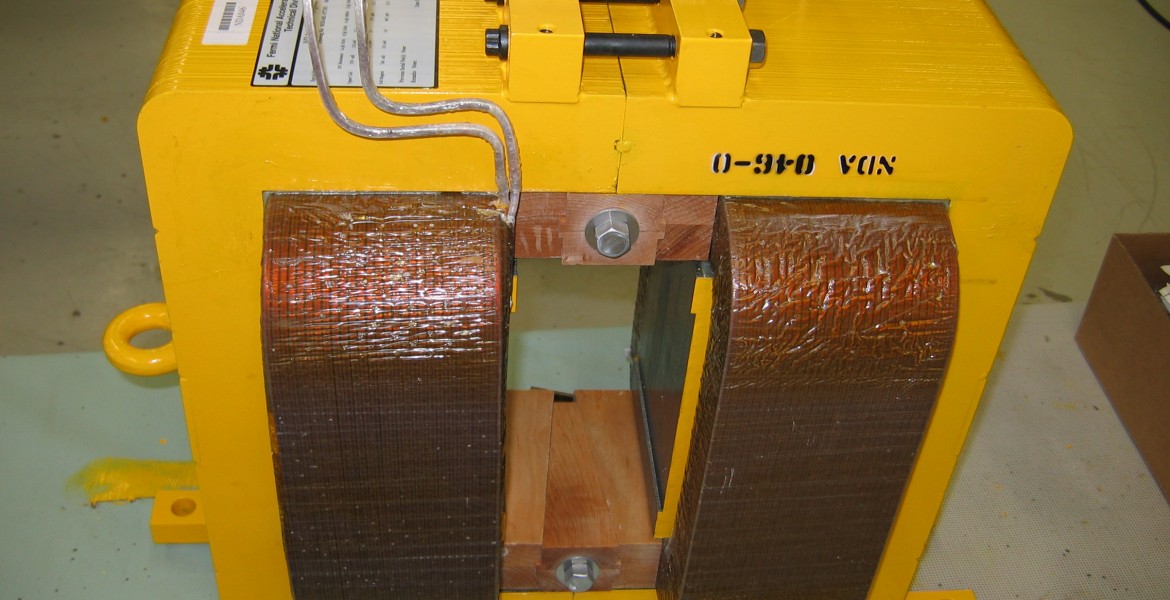

Nevertheless, APS-TD has and is building conventional magnets in small and large numbers. We provide support for the Fermilab accelerator complex by repairing or refurbishing existing accelerator magnets and magnet components, as well as designing, fabricating and testing of new devices for improvements of the existing accelerator complex. In-house we have the following capabilities, among others:

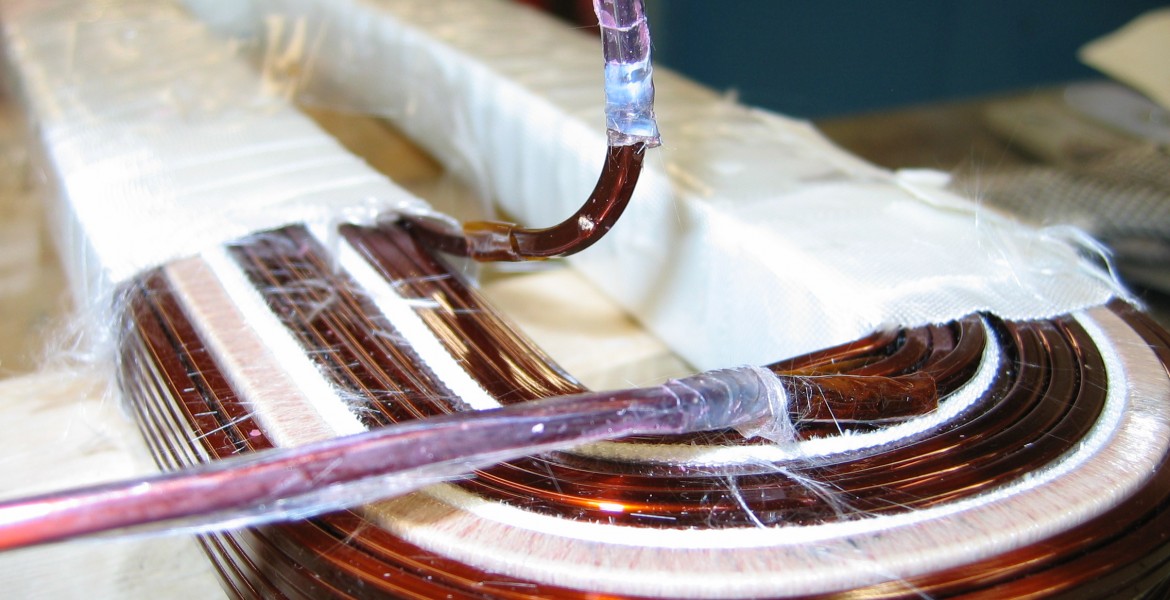

- Vacuum-pressure impregnation for large objects

- Winding of large not regular magnet coils, including SC coils

- Producing small SC magnetic devices

- Producing accelerator, non-common type, magnets for field injections and extraction

- Manufacturing small batches of non-standard superconducting cables

- Reaction and test of the HTS strands or any other materials in oxygen/argon environment

Magnet Testing

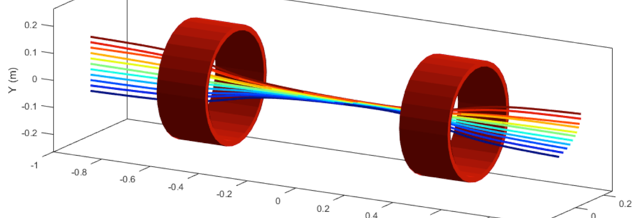

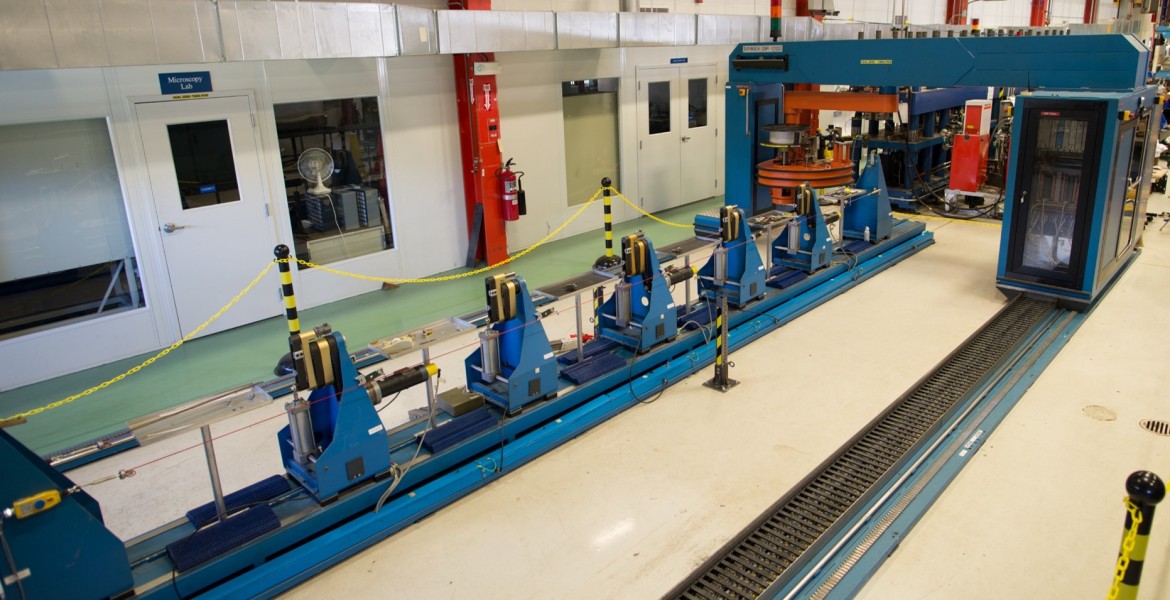

No magnet is leaving APS-TD before its performance and field quality was carefully evaluated. Several test stands for conventional and superconducting magnets are utilized to determine the components of the magnetic field, the power consumption and heating of conventional magnets or the quench performance of the superconducting devices. Among the many test capabilities are:

- Measurement of complex magnetic fields

- Analysis of the complex magnetic fields

- Magnetic measurement systems include:

- Rotating coil systems

- Single Stretch Wire systems

- Calibration Magnets

- Hall and NMR probes

- Infrastructure and test stands for currents up to 30kA

- For superconducting magnets additional qualifications measurements include:

- Training curves (for superconducting magnets)

- Temperature and ramp rate dependence of the quench current

- Inductance and energy loss

- Magnet quench protection studies

- Splice resistance

- RRR characterization

Conventional Magnets

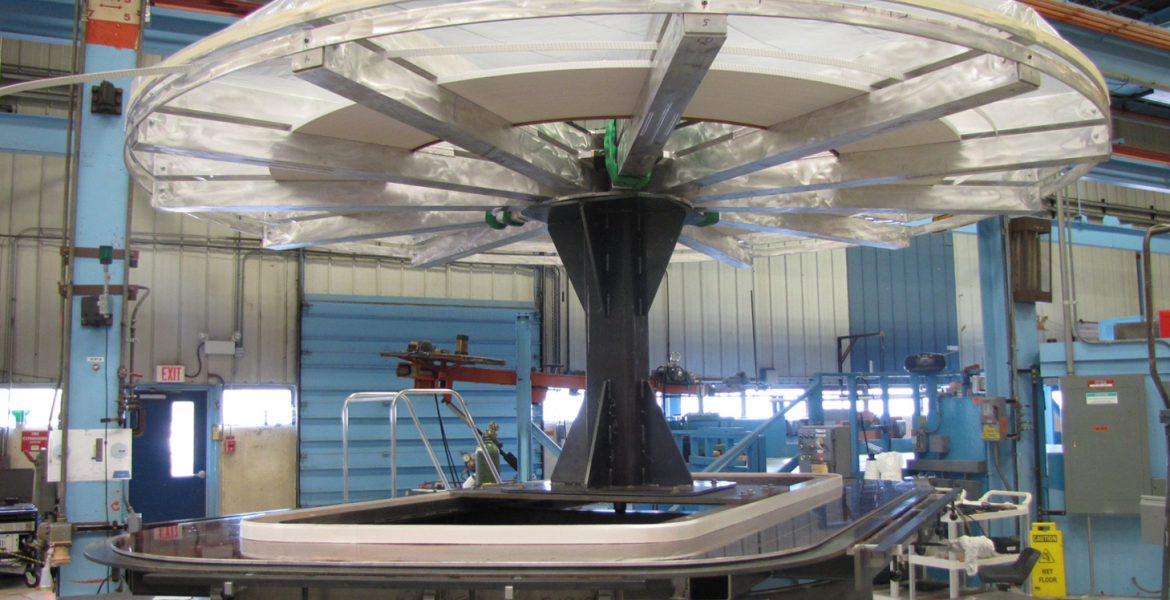

APS-TD has the capability to design, manufacture and measure any type of conventional accelerator magnet. This requires diverse expertise as designs span from extraction or injection kickers and Lambertsons, to strong bending dipoles and focusing quadrupoles, or relatively small, multi-element corrector magnets. Additionally, we design and fabricate fast-ramping AC magnets, as well as gradient-field magnets for specific accelerator applications.

Superconducting Strand and Cable R&D Lab

The robust and versatile infrastructure that was developed at Fermilab in support of advanced superconductor and accelerator magnet development, together with the expertise acquired by the magnet scientists and engineers in design and analysis tools for superconducting materials, cable and coil technologies, makes Fermilab an ideal setting for exploring superconducting accelerator magnets at the limit of Nb3Sn capabilities and beyond. Since 1998 the Fermilab Superconducting R&D Lab has served as ideal stage for hands-on training of 34 graduate students in Physics and Engineering on superconductivity, materials science, mechanics, heat transfer, cryogenics, electronics, computing and automation during summer internships or PhD theses.

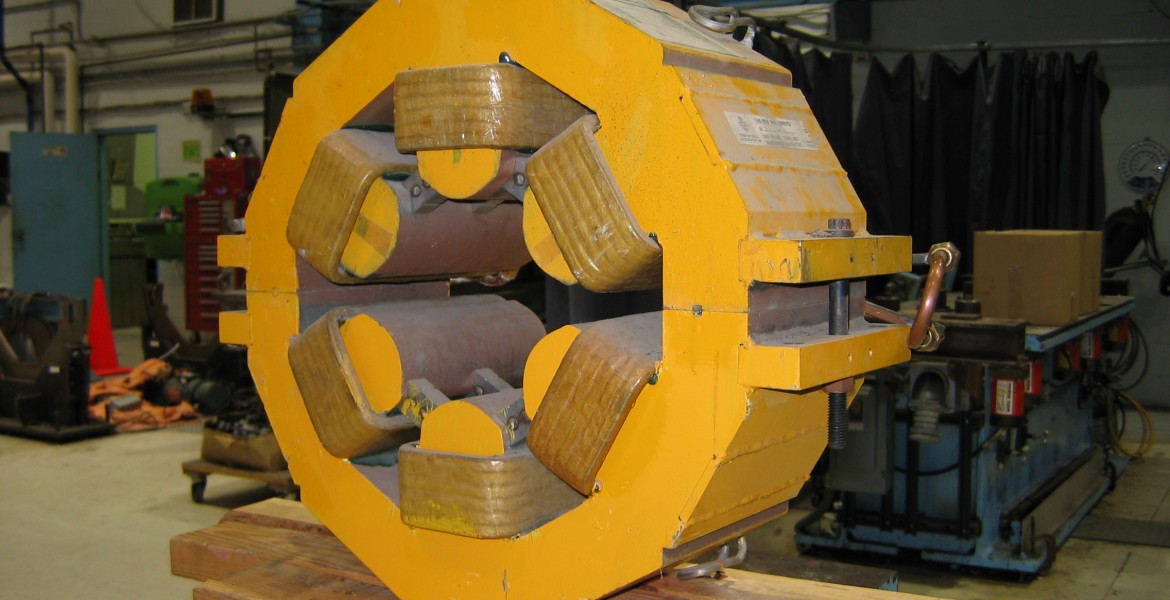

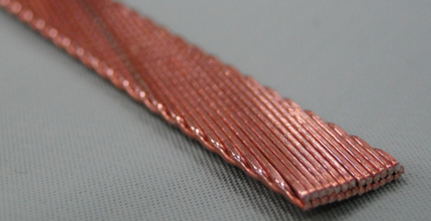

Cabling development

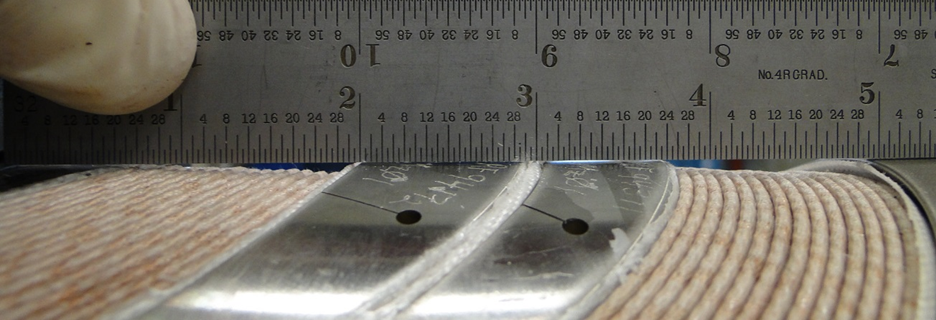

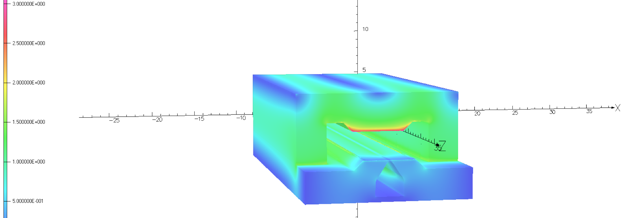

Cable development is performed by designing and fabricating samples of different geometries using state-of-the-art wires, with the purpose of studying the effect of cable parameters and processing on its performance. This includes for instance the sensitivity of electrical properties (Jc, RRR) and internal structure (diffusion barrier, subelement shape and spacing) to cable compaction, measurements of cable stability and AC losses, measurements of 3D cable expansion during the fabrication process and during reaction, effects of intermediate annealing when using a 2-pass fabrication process, etc. Rutherford cable finite element models (FEM) that allows evaluating for each considered cable geometry what is the plastic strain seen by the strands during fabrication, what are the most critical strand locations, and predicting local damage whenever the failure mechanisms of a specific strand technology are known, were produced at Fermilab to aid in cable design.

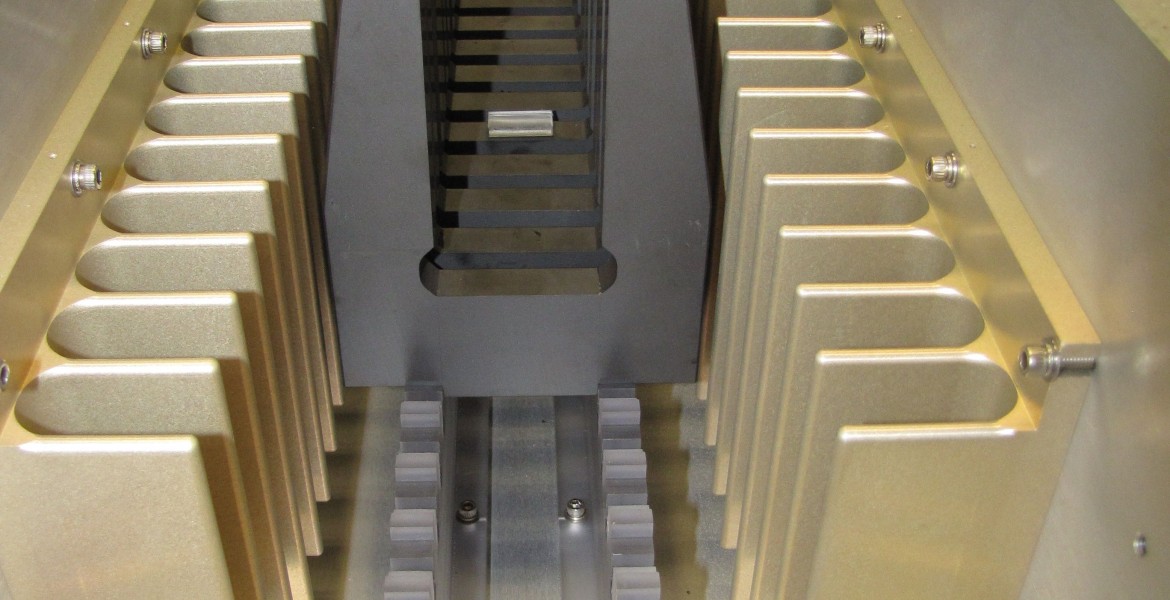

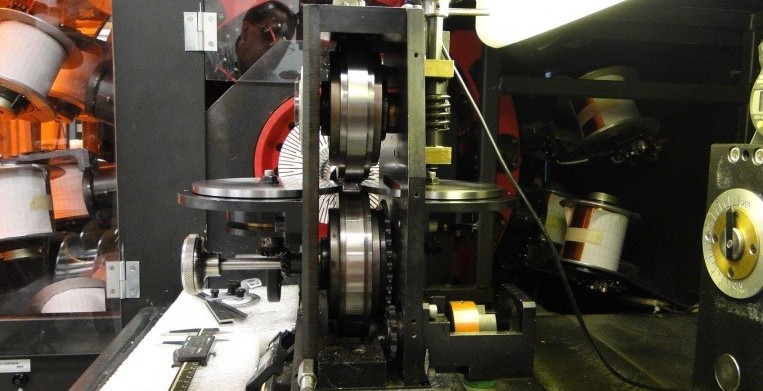

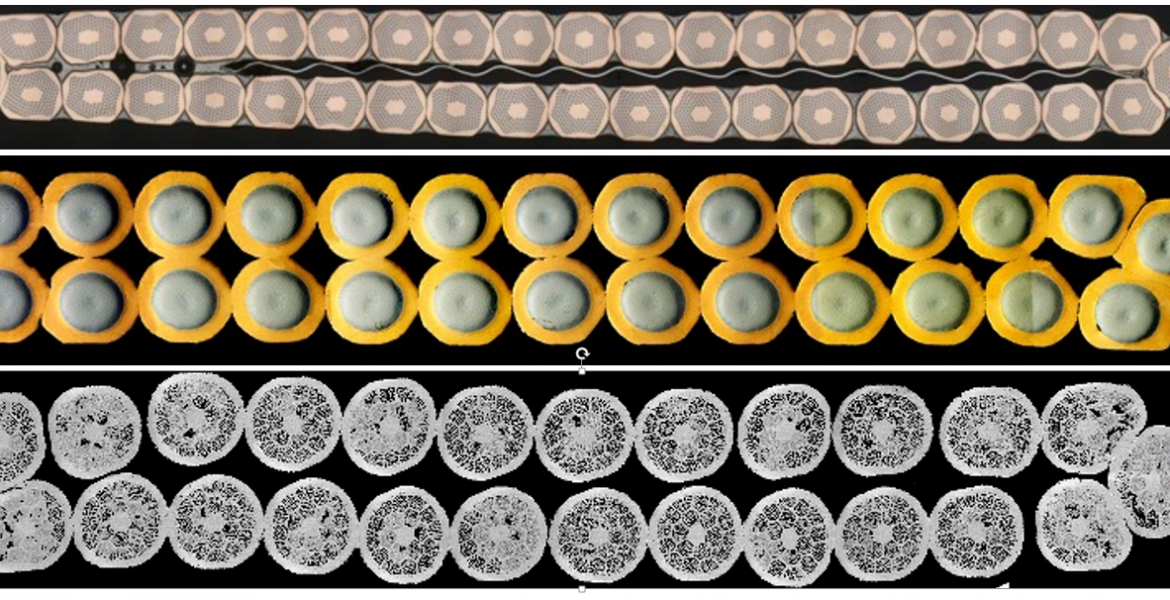

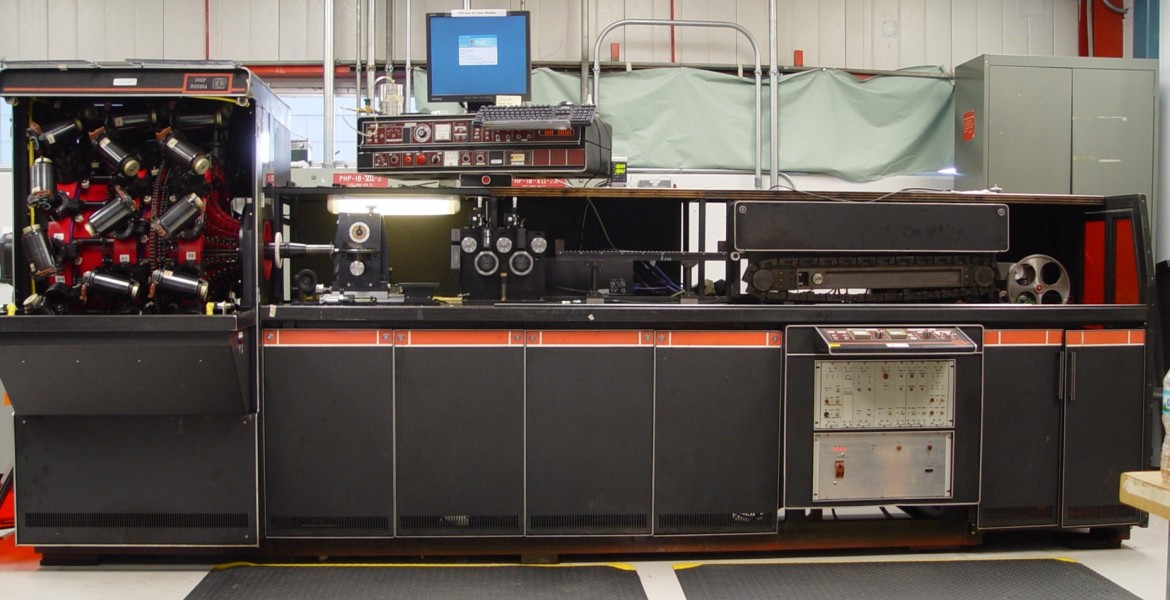

The Cabling Facility, located in the Fermilab’s APS-TD, includes a compact cabling machine with 42 spools and electronic synchronization for lay angle control, a re-spooler, sets of forming fixtures, mandrels and measuring devices. Operations include re-spooling of strands, transposition of strands into a cable and forming of the cable with a round, rectangular or keystoned cross section, control of the cross section size, and cable spooling onto the pick-up reel. Cable quality control includes measurements of the strand diameter, visual inspection of the cable during fabrication to check for cross-overs and other possible imperfections, measurements of cable thickness and width, microstructural analysis of cable cross sections, and electrical characterization of both virgin and extracted strands.

Equipment

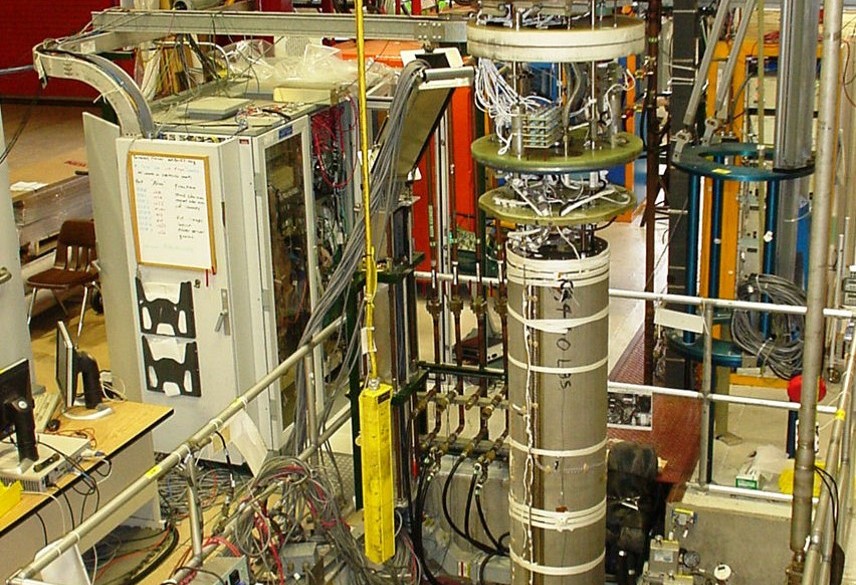

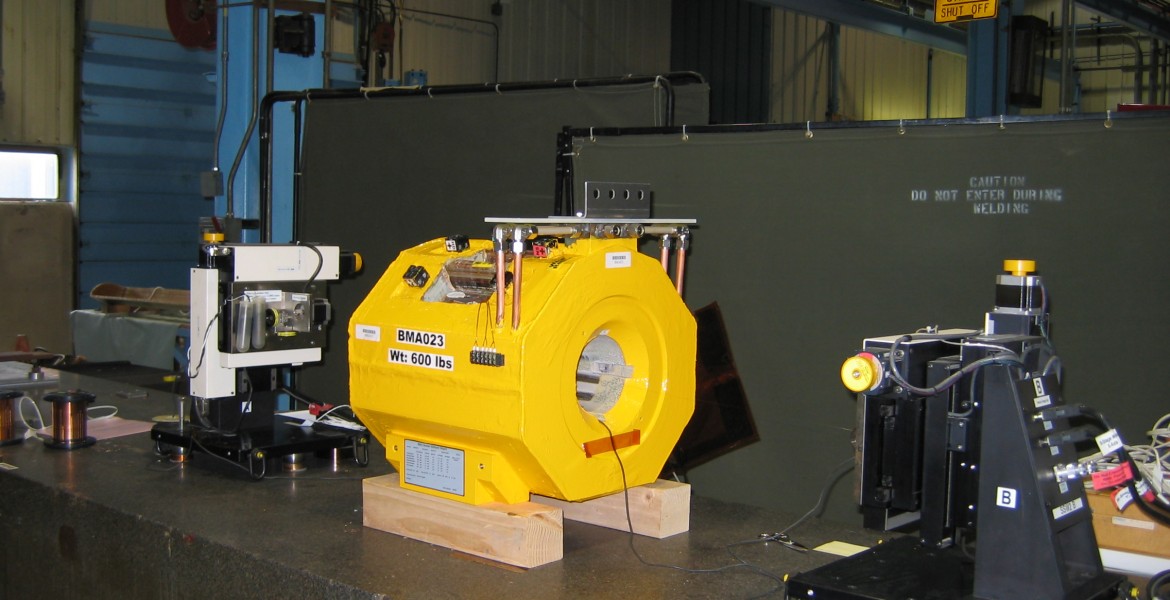

At present the Superconducting Strand and Cable R&D lab includes the following cryogenic equipment:

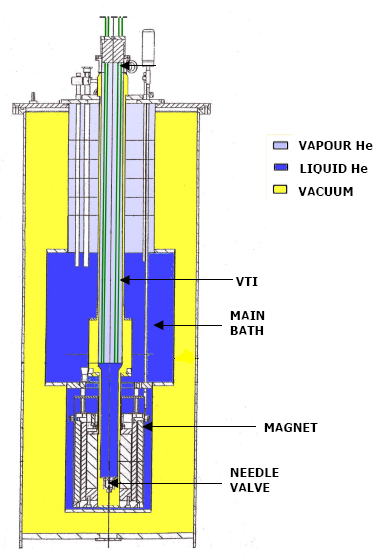

- Teslatron 1, a 15T/17T magnetic cryostat by Oxford Instruments with 64 mm cold aperture and a Variable Temperature Insert (VTI) for measurements between 1.5 K and 300 K (see schematic in Fig. 8). Master and slave power supplies provide 1875 A. The DAQ includes current, voltage, temperature, magnetic field and helium level readings, as well as quench protection.

- Teslatron 2, a 14T/16T magnetic cryostat by Oxford Instruments with 77 mm cold aperture and a VTI for measurements between 1.5 K and 300 K. Master and slave power supplies provide 2000 A. In addition to the same readings as above, the DAQ for this system also includes an integrator for magnetization measurements and for high current measurements through a Rogowski coil.

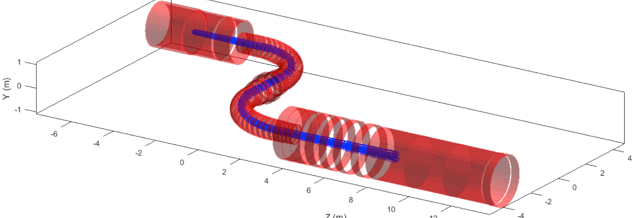

- Teslatron 3, a vacuum insulated liquid helium dewar of ~50 liters with a neck of 253 mm. The power supply provides 2400 A. The DAQ includes current, voltage, temperature, magnetic field and helium level readings, as well as quench protection. This cryostat can be used to test stand-alone coils with maximum OD of 252 mm, and was used to test HTS helical coils.

- Teslatron 4, an 8.5T/10T magnetic cryostat of 75 liters by Oxford Instruments, with 147 mm cold aperture. The power supply provides 2400 A. The DAQ includes current, voltage, temperature, magnetic field and helium level readings, as well as quench protection. This system is being presently used to measure shielding capabilities of bulk MgB2 tubes for the Muon g-2 Project.

- A low temperature cell loader for strain gauge calibration both at room temperature and at 4.2 K.

The Lab also includes the following equipment:

- Four tube furnaces of ~6 inches diameter and of at least 12 inches homogeneous length for heat treatment of superconductors in argon and oxygen up to 1500ºC.

- A 2 m long furnace for heat treatment in air and in argon up to 1250ºC.

- A metrology well calibrator for accurate ovens’ thermocouple calibration up to 700ºC.

- A motorized flat-rolling system to impart plastic strain within a desired range to round superconducting wires, usually before heat treatment, for superconductor studies. The strand is flattened vertically, and it is free to expand laterally. Wire deformation is defined as (d-t)/d, where d is the original strand diameter and t is the thickness of the deformed strand.

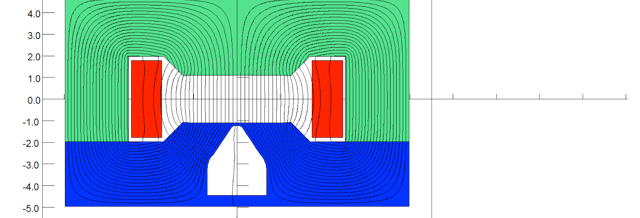

Schematic of a typical magnet, cryostat and VTI assembly.

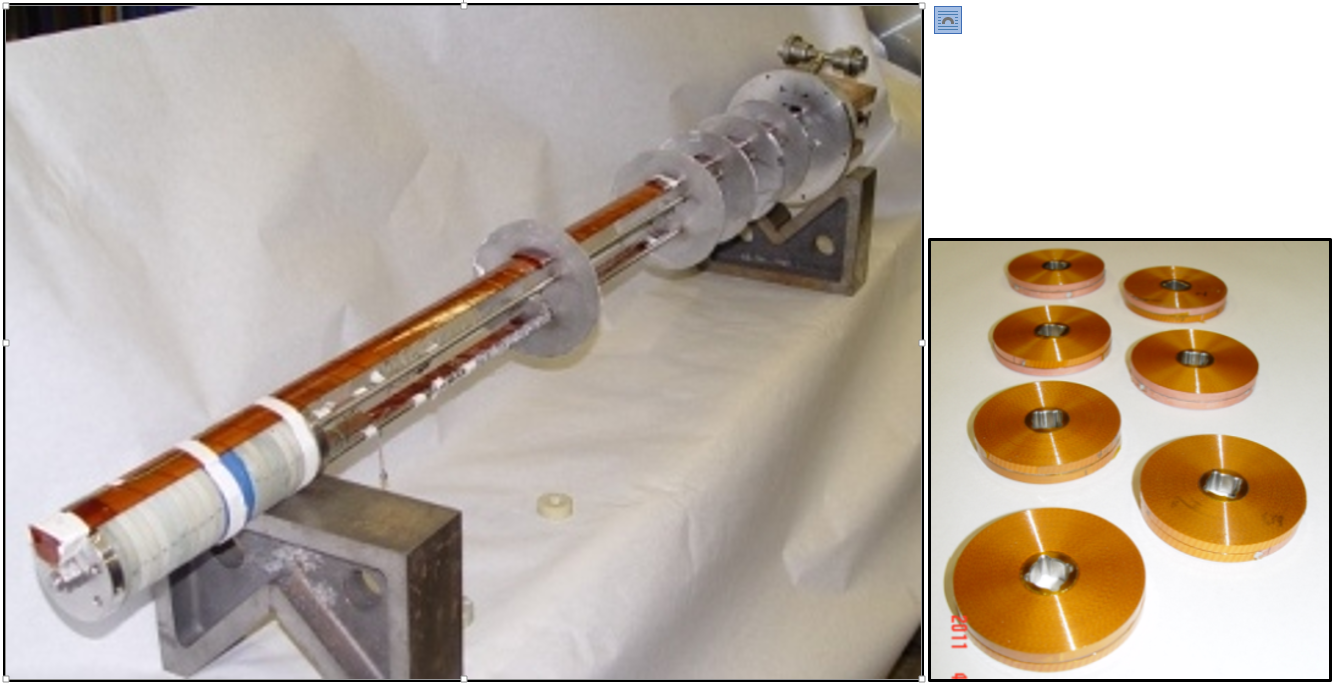

Modular Insert (left) designed to test double pancake coils made of YBCO superconductor (right) in Teslatron 2.

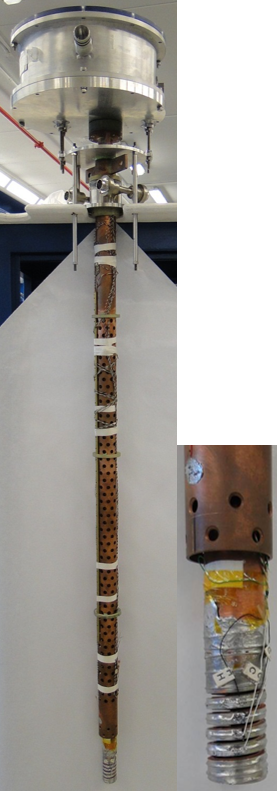

A Walters’ spring-type device for tensile/compressive strain sensitivity studies of Jc in superconducting wires up to ~0.1% strain, 15 T, 2 kA at 1.9-300 K for operation in Teslatron 1.

Measurements

The variety of measurements conducted on cables and strands in the Lab include:

- Strain sensitivity

- Magnetic field

- Short sample limit

- Critical current

- RRR

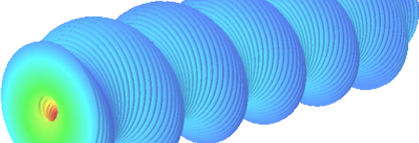

- Flux jump stability and magnetization

Measurement examples

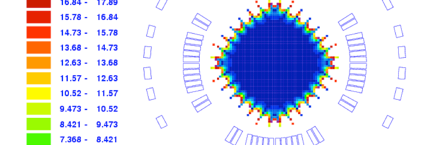

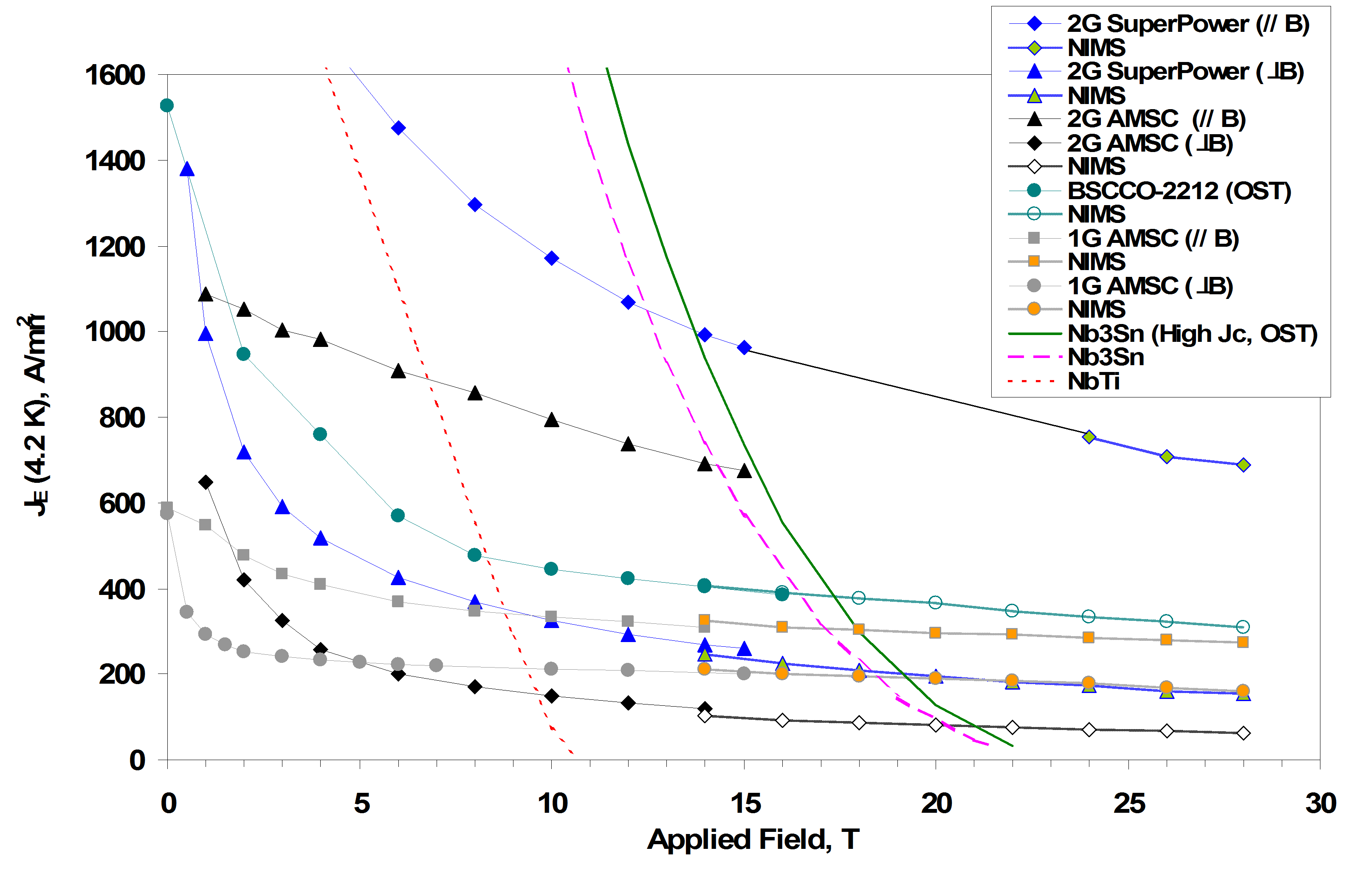

Engineering critical current density at 4.2 K of a number of Low Temperature Superconductors and High Temperature Superconductors obtained as a function of magnetic field.

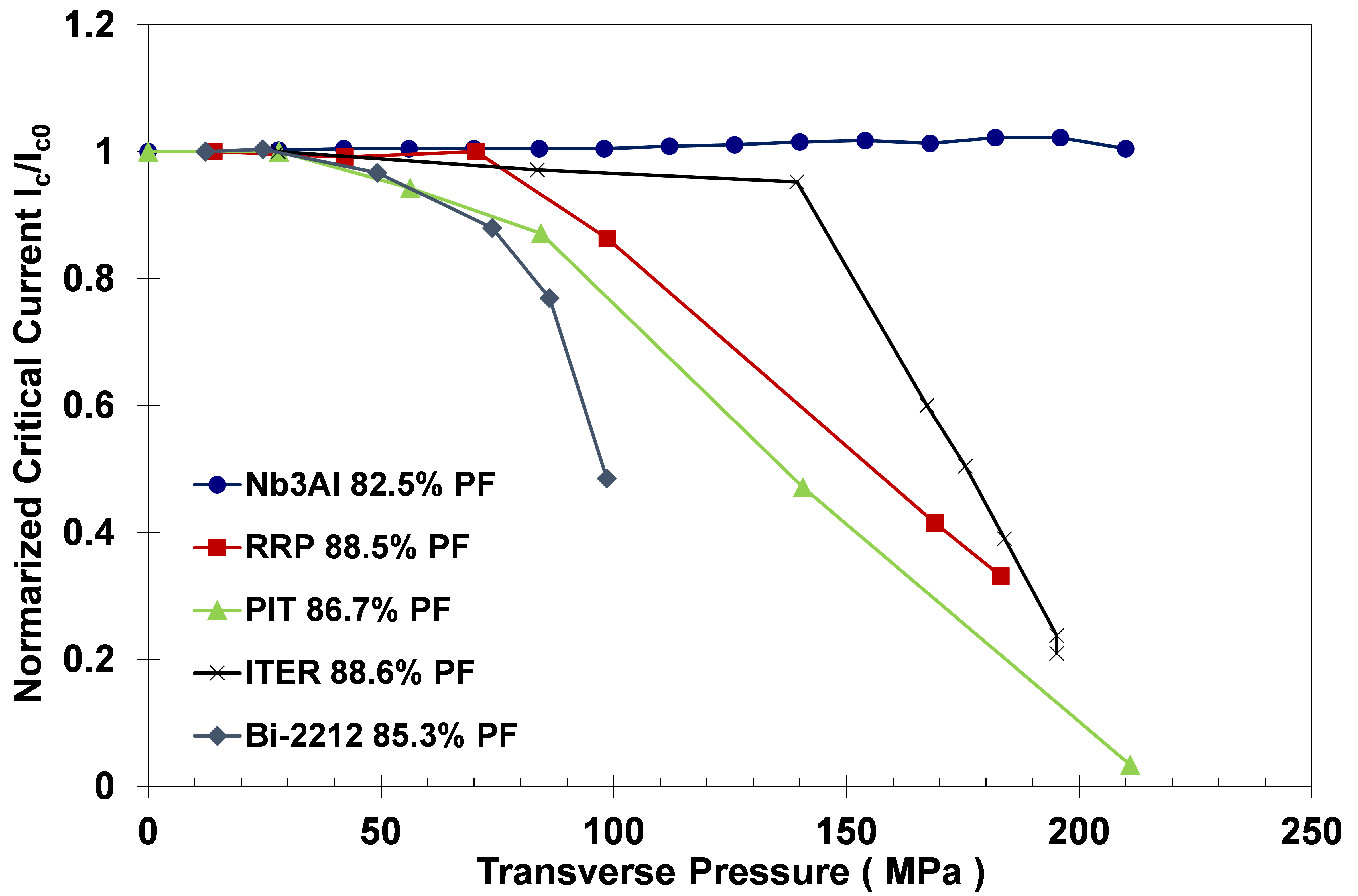

The Ic sensitivity of a number of superconductors to transverse pressures up to 210 MPa. It should be noted that these data represent the effect of uni-axial and not multi-axial strain, since the experimental setup allows for the sample to expand laterally. This produces larger strain values on the cable sample than for instance on a laterally constrained one, and therefore these are conservative results with respect to what is typically seen in magnet coils.

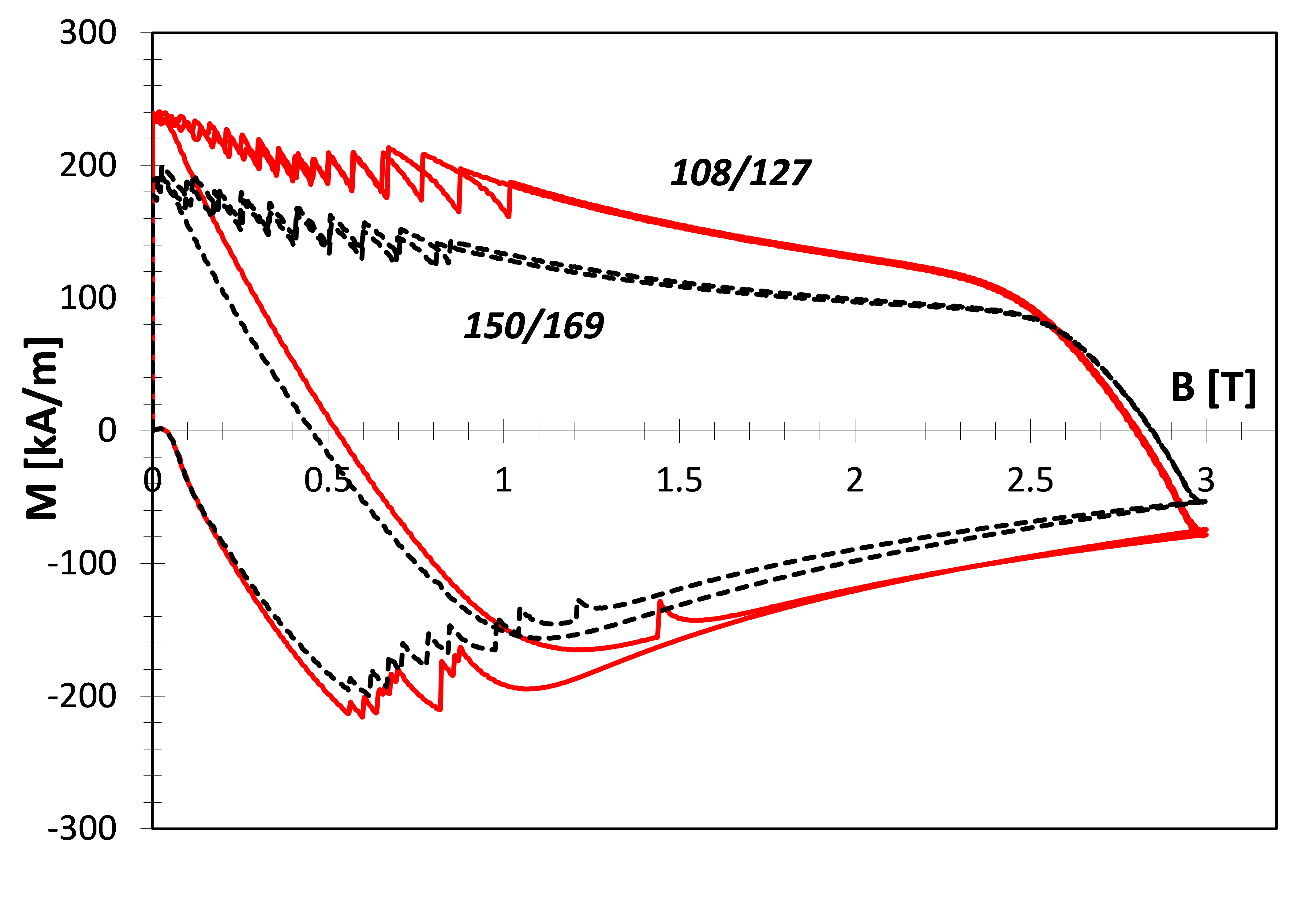

Magnetization measurement performed at 4.2 K for two 0.7 mm Restacked-Rod Process (RRP®) wires between 0 and 3 T per total strand volume. Both wires show flux jumps.